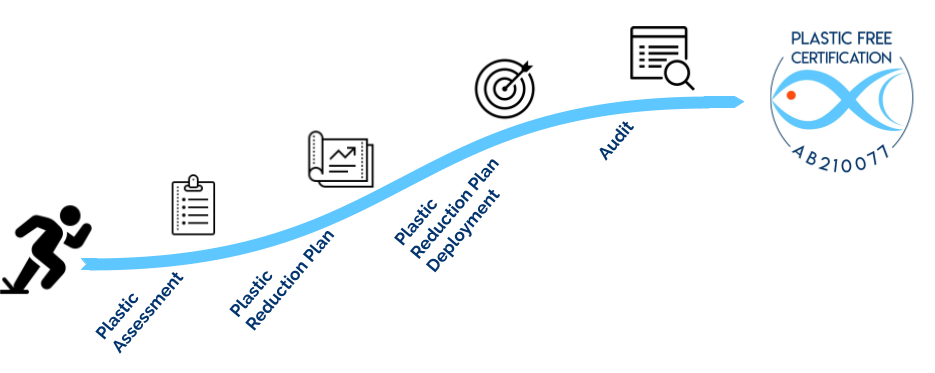

Development of a Plastic Reduction Plan to identify concrete reduction actions. For each item, with the support of a consultant, opportunities for reduction, elimination or replacement are assessed and actions to be implemented over a one-year period are determined.